Aluminum Sheet Fabrication: Formed and Finished

Aluminum sheet fabrication is the process of taking flat aluminum sheets and transforming them into finished metal parts through cutting, forming, and joining. This manufacturing process provides the flexibility to design parts that are lightweight yet durable, making it one of the most relied-on fabrication techniques across industries. Aluminum’s appeal lies in its ability to […]

CNC Machining for OEMs: Scalable Precision Parts

Original equipment manufacturers (OEMs) operate in highly competitive markets where efficiency and accuracy directly impact success. Each finished product depends on the strength of its parts, and even small delays or defects can disrupt the entire supply chain. Precision CNC machining is crucial for OEMs, offering a reliable method to produce parts that meet exact […]

CNC Precision Machined Components: Built to Spec

CNC precision-machined components are parts produced by milling machines and turning centers following programmed instructions These machines control the cutting tool’s movements to remove material from stainless steel, aluminum, or titanium with great accuracy. The result is a finished part that consistently reflects the original design, no matter how complex the geometry. Unlike traditional methods, […]

Precision CNC Components: What You Should Know

Hibshman delivers: Expedited productionCustom production runs on your timelineFirst article inspectionsOn-time deliveryA scrap rate of just 0.1% Precision CNC components are parts created through computer numerical control (CNC), a process where digital programming guides cutting tools with extreme accuracy. Unlike traditional machining, where some variation is acceptable, high-precision CNC machining produces components that meet […]

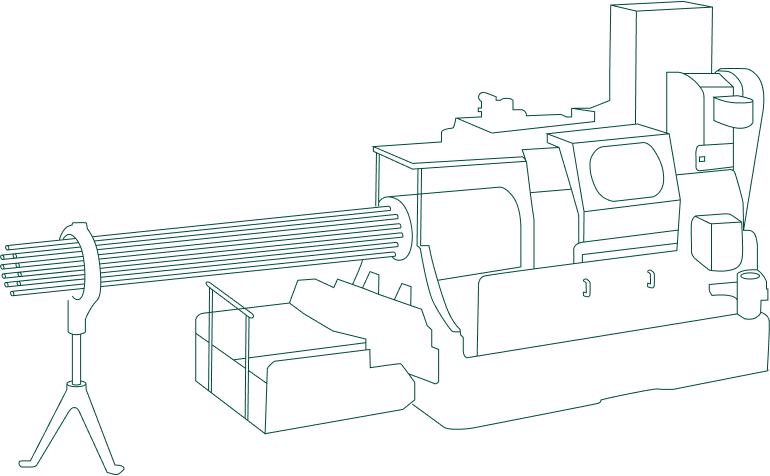

CNC Turning Machine Parts: Fast and Repeatable

CNC turning machine parts are components made through subtractive manufacturing, where material is removed to form precise shapes. They are most often cylindrical parts such as shafts, bushings, fasteners, and threaded features. This technology is widely deployed because computer numerical control (CNC) ensures repeatable, high-accuracy results across small batches and large production runs. If you […]

High Precision CNC Machining: Details That Define Performance

High precision CNC machining is a manufacturing process that produces parts with extremely tight tolerances, often within a few thousandths of an inch. This level of accuracy is necessary when components must fit exactly with other parts or operate reliably under stress. In demanding industries like aerospace, medical devices, or advanced automotive systems, even the […]

Swiss Precision Manufacturing: Built for Complexity

Swiss precision manufacturing is a specialized machining process designed to produce small, complex parts with outstanding accuracy. Unlike traditional lathes, Swiss machines secure the workpiece in a guide bushing positioned closely to the cutting tool. This setup helps reduce deflection and vibration, which is essential when dealing with components measured in millimeters. The outcome is […]

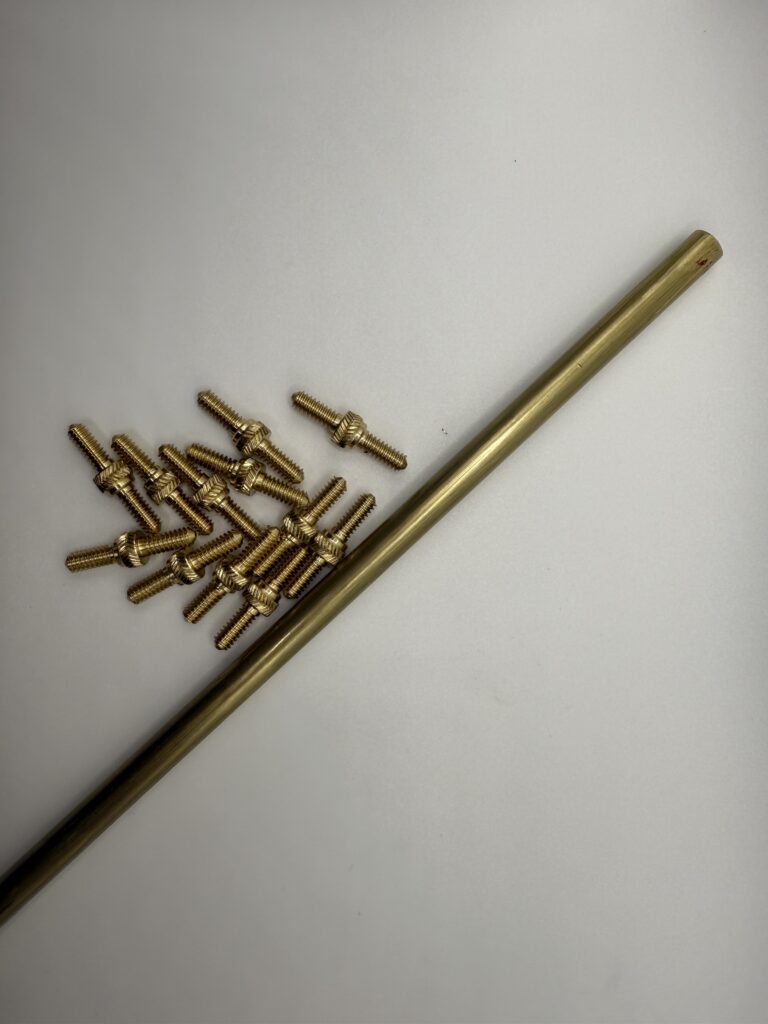

Swiss Screw Machine Parts: Precision in Every Turn

Swiss screw machine parts are small, detailed components created on highly specialized turning machines designed to achieve accuracy and consistency. Unlike conventional lathes, these swiss screw machines support the material close to the cutting tool with a guide bushing. This design reduces deflection and makes it possible to hold extremely fine tolerances. The result is […]

Swiss Screw Machine Parts: Precision at Every Turn

Swiss screw machine parts are essential to industries where precision, repeatability, and diminutive dimensions are non-negotiable. These parts are best made on Swiss-type lathes—machines built to handle small parts with high accuracy and smooth finishes, even during complex, nonstop cutting. Why Choose Swiss Machining for High-Volume Precision Parts? Swiss screw machine parts typically have intricate […]

Swiss Lathe Machine Shop: Precision at Scale

Modern manufacturing requires the ability to scale without compromising quality. As industries like aerospace, medical devices, and electronics push the limits of miniaturization and performance, the machinery behind these innovations must evolve in lockstep. These sectors rely on high-precision components for critical assemblies, such as surgical instruments, aerospace connectors, and micro-electronic enclosures, where consistency and […]