Hibshman Screw Machine Products

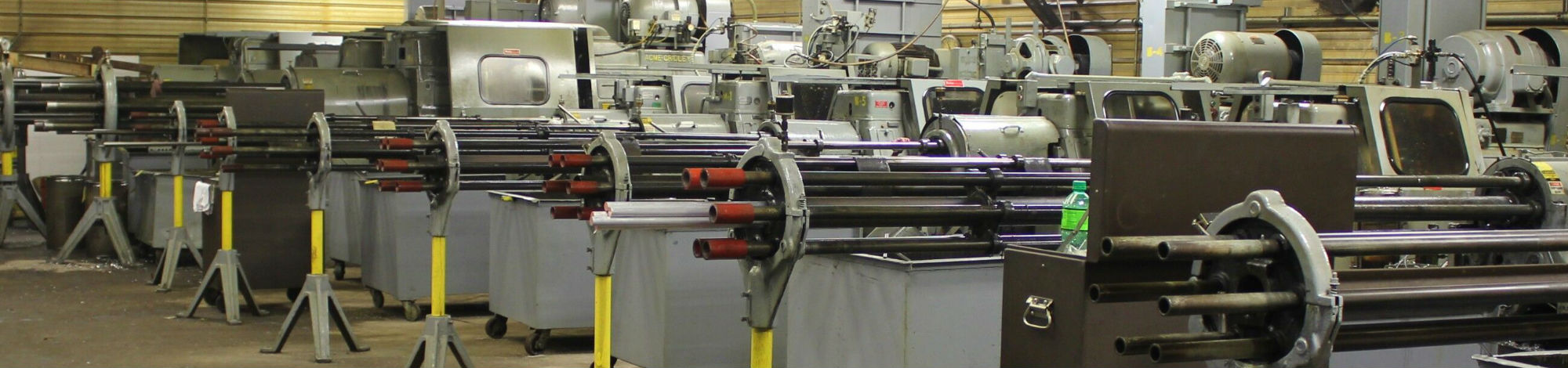

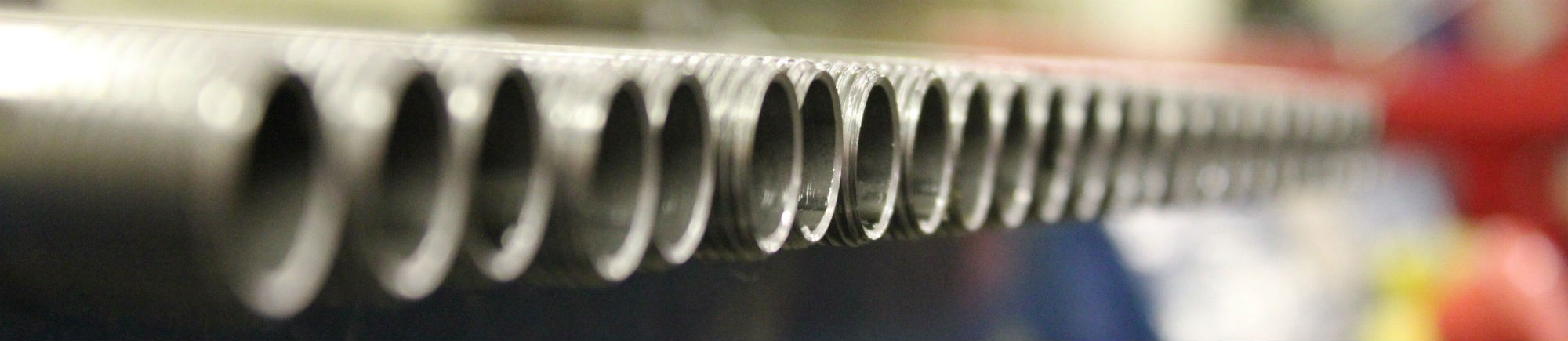

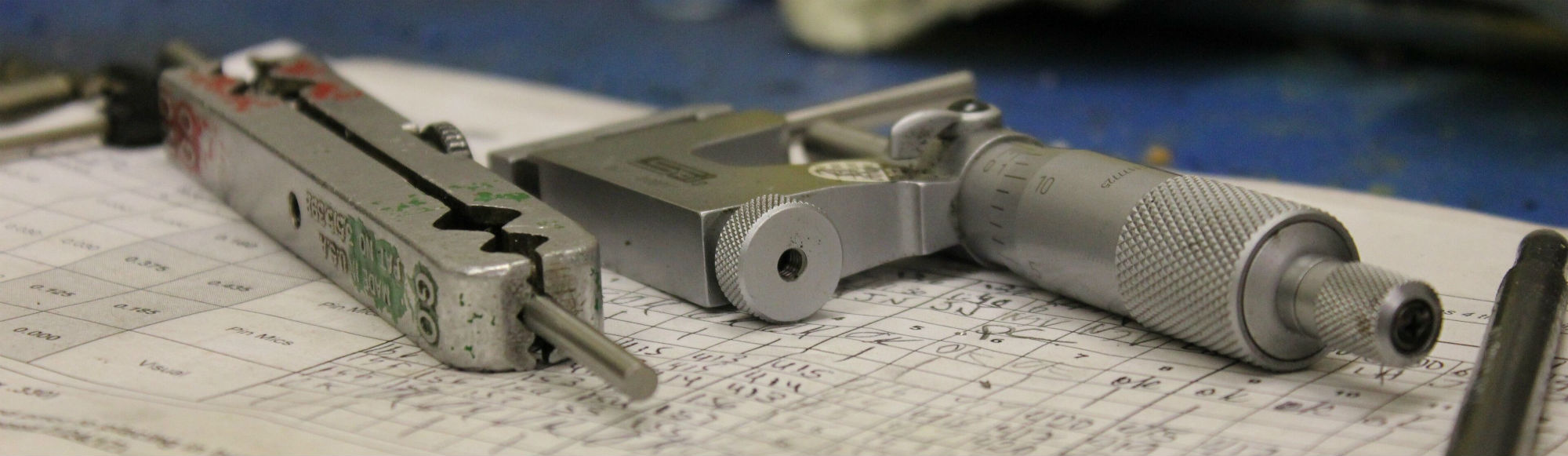

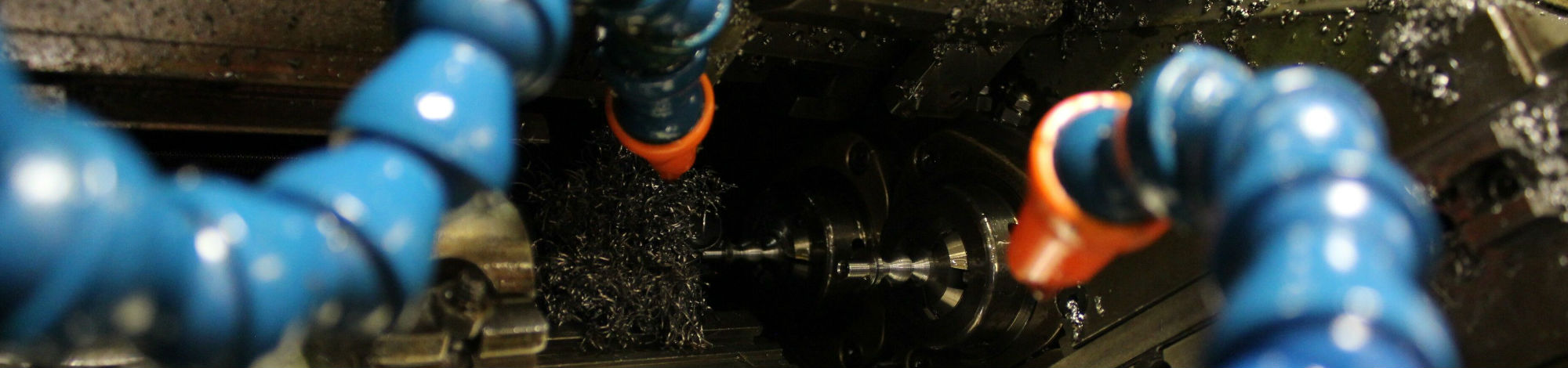

Hibshman Screw Machine Products welcomes short and long runs from 100 to 1,000,000 pieces. Our 60,000 sq. ft. building houses Brown & Sharpe single spindles and Acme Gridley multi-spindles with 1/16" to 3-1/2" diameter capacities. Our screw machine capabilities are complemented by complete in-house secondary operations.

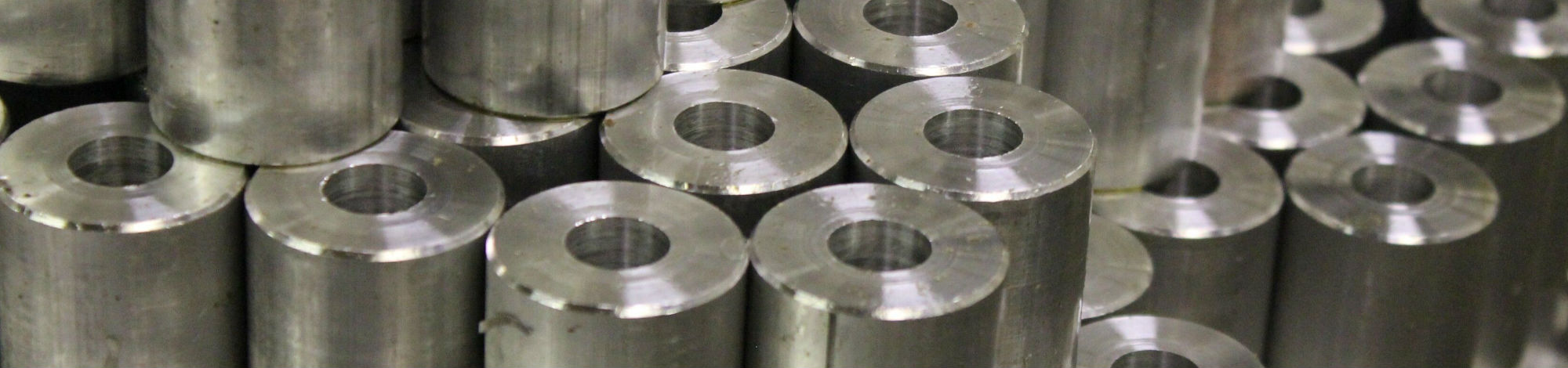

We provide parts made from:

Stainless Steel, Steel, Copper, Plastic, Nylon, Aluminum, Brass

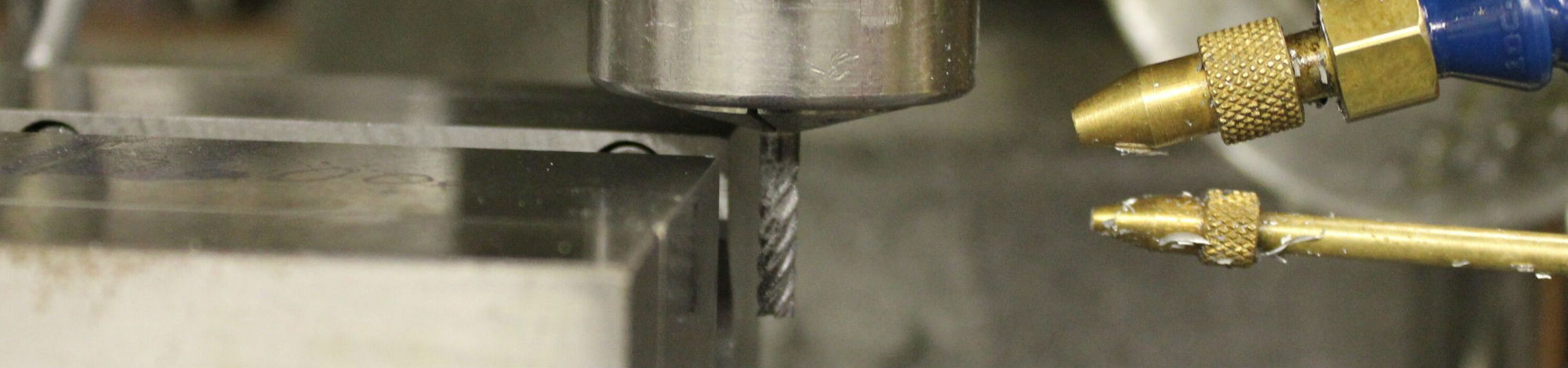

Secondary operations include:

Automatic Turret Lathes, Milling Machines, Stamping Presses (maximum 100 ton), Drill Presses, Automatic Drilling and Tapping, Grinding, Tube Bending, Vibratory Finishing, Rotary Welders, Fabricating and Assembly

New for 2022

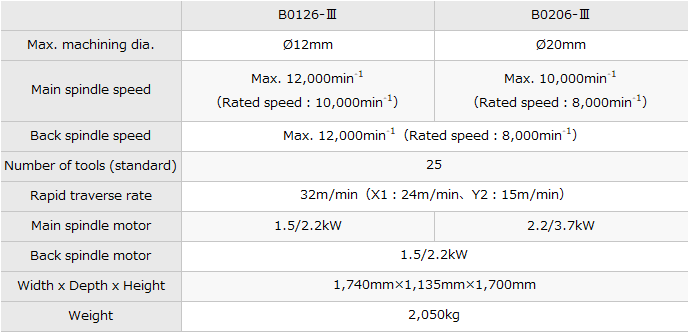

Tsugami B0206-III Automatic Precision Lathe

- Back tool post with Y axis on the compact body

- Milling capability is improved on the back side machining.

- The back tool post with Y axis enables the simultaneous operation of back spindle side complex machining with main spindle side machining.

- Realizes complex workpiece machining by the live tools (option) and the main spindle C-axis control (option).

- Guide-bush type or guide-bushless type is selectable according to workpieces. (option)

- Automatic programming software is provided as standard.

NEXTURN SA(B) 7-AXIS SWISS LATHE SERIES

- Synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm

- Built-in motor on main spindles range from 3 – 10 HP and maximum RPM capacity up to 10,000 RPMs, while sub-spindles offer 1.5 – 3 HP and up to at 10,000 RPMs

- Full C-axis with .001° positioning

- Excellent rigidity results from the use of FEA technology in the one-piece bed casting design

LICO LNT Series | CNC Multi-Slide Automatic Lathe

- Extra wide span between Z-axis linear ways with full travel support largely increases machining stability and accuracy.

- X2 Z2, X3 Z3, X4 Z4 ball screws are directly driven by Siemens servomotors.

- Precision linear guideways on Z1axis.

- Automatic lubrication to all slideways.

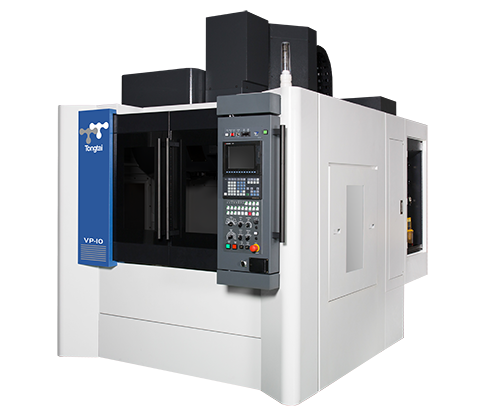

VP-10 | Vertical Machining Center

- High quality direct-drive spindle and high rigidity structure design

- BBT-40 spindle, supports dual contact tool holder

- Excellent precision and cutting capability

- General purpose model, suitable for all types of processing industries

- High cost performance value

| Specification | VP-10 |

| Table size(LxW) | 1070x510 mm |

| Max. loading capacity | 500 kg |

| X/Y/Z axis travel | 1020/510/600 mm |

| X/Y/Z axis rapid traverse | 36/36/36 m/min |

| Spindle taper | 7/24 Taper No.40 |

| Spindle speed | 10000 (15000) rpm |

| Spindle motor | 11/7.5 (15/11/7.5) kW |

| Tool capacity | 24 (30) pc |

Automatic Screw Machine Equipment

| 6 | No. 00 | Brown & Sharpe Square Base 1/2" capacity |

| 2 | No. 0G | Brown & Sharpe Square Base 3/4" capacity |

| 2 | No. 2 | Brown & Sharpe Square Base 3/4" capacity |

| 2 | No. 2 | Brown & Sharpe Ultramatic Base 3/4" capacity |

| 6 | No. 2 | Brown & Sharpe 1-1/4" capacity |

| 5 | No. 2 | Brown & Sharpe 1-1/2" capacity |

| 1 | No. 2 | Brown & Sharpe 3/4" capacity |

| 2 | 7/16" | Acme Gridley 6 spindle RA-6 |

| 4 | 9/16" | Acme Gridley 5 slides, 6 spindle with threading |

| 8 | 1" | Acme Gridley 6 spindle RA-6 with threading |

| 2 | 2-5/8" | Acme Gridley 6 spindle with universal threading and tapping |

| 1 | 1/2" | Acme Gridley RB 4 spindle |

| 1 | No. 2 | Warner Swasey Turret Lathe |

| 1 | 16" | South Bend Engine Lathe with 3 jaw chucks |

| 3 | Hardinge Super Precision Lathe | |

| 1 | 16" | Max Turn Engine Lathe |

| 2 | 1/2" | Lipe Automatic Bar Feed |

| 1 | 3/4" | Lipe Automatic Bar Feed |

| 1 | 1-1/2" | Lipe Automatic Bar Feed |